Location: North Bergen, N.J.

Square Footage: 607,000-squarefoot multi-tenant facility

Products Handled: Consumer products, fashion, cosmetics, health care, medical equipment for home use and electronics

Throughput: Up to 160,000 units per week in receiving; 80,000 orders per week and returns of up to 12,000 units per week

People/Shifts: 3 Shifts per day/6 days per week

Bergen Logistics uses a variety of order fulfillment solutions in its New Jersey location, depending on the client, including a goods-to-person robotic system.

Bergen Logistics’ more than 600,000-square-foot e-commerce fulfillment facility in North Bergen, N.J., handles a variety of products across several industries. To make it all happen, the 3PL relies on a number of technologies, depending on product type. One of the showcase technologies is a goods-to-person robotic fulfillment solution.

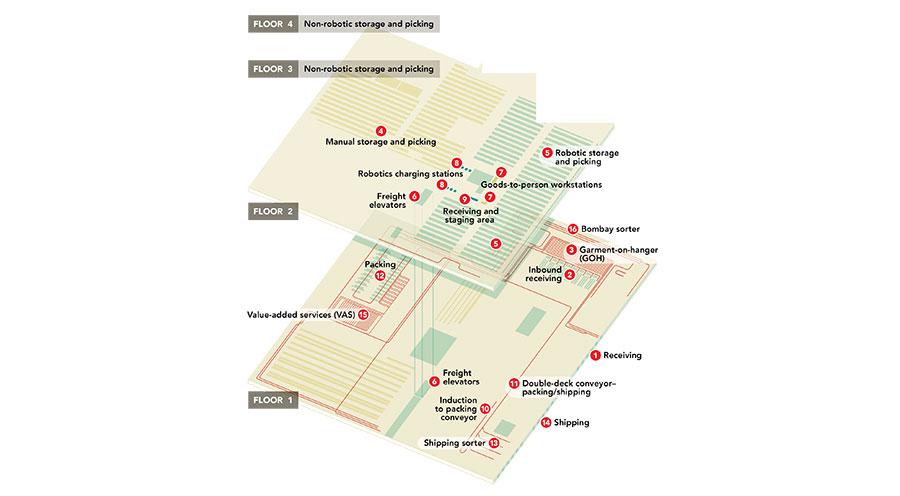

Moreover, it does so in a multi-level environment. Receiving, returns, value-added services (VAS), packing and shipping take place on the ground level.

That level also includes a 40,000- square-foot area for high-bay storage. The second level includes robotic storage and picking plus a manual picking area. Conventional picking takes place on the third and fourth levels. For this article, we’ll focus on the goods-to-person robotic fulfillment solution on the second level.

Receiving

Product is received at the docks (1) and then processed for putaway at an inbound receiving area (2). Product that will be stored and picked on hangers is received in a garment-on-hanger (GOH) area (3). Some product destined for storage in a manual picking area (4) on the second floor. Finally, there is product destined for storage in the robotic processing area on the second floor (5). The robotic system is designed to work with corrugated bins that measure 40 centimeters wide, 60 centimeters long and 20 centimeters high. Some of that merchandise is received in boxes with those dimensions and can go into storage without re-packing. In those instances, the box is scanned and opened, the flaps are removed and an associate counts the items to verify the quantity. Boxes that are out of dimension are scanned into a box designed for the system. In either case, the boxes are palletized, and the pallet is taken by elevator to the second level with freight elevators (6).

Putaway

On the second floor, some product will be put into storage in the manual area. The remainder is putaway into the robotics area. The robotic fulfillment solution works with two different sized robots. The first is a large robot that looks a little like a scaled down lift truck.

It puts bins away into storage and then retrieves them and moves them to a floor level pickup location in the storage area for order fulfillment. A smaller, bin handling robot retrieves bins and delivers them to one of two goods-to-person workstations (7) and then returns them to the storage area after demand for that bin has been satisfied. When the robots are not in use, they can charge at one of the opportunity charging/parking stations (8).

To initiate the putaway process, an associate scans a bin into a storage location that is essentially a large putwall (9). That alerts the large robot that a bin is ready for putaway in the storage area. It’s retrieved from the storage location and then delivered to storage. The bin is now available to promise. Replenishment in this area is the same as the initial putaway.

Order fulfillment

Orders are received into Bergen Logistics’ proprietary Cloud-based warehouse management system (WMS). The WMS, in turn, transmits the orders to the robotic execution system. That system then prioritizes orders based on cutoff times. Once the order of work has been determined, the large robot begins retrieving bins from upper level storage locations and re-locating them to open slots on the lower storage level.

The small robot then automatically retrieves bins and delivers them to a goods-to-person workstation designed to work with the robots. A lift raises the bin to the work level for the associate, who receives picking instructions on a screen. When the associate scans the items, a put location lights up on an adjacent putwall. Once all the required items have been removed from a bin, the small robot returns it to a first level location. It will subsequently be reslotted by the large robot.

Packing

An associate on the other side of the putwall scans the items into totes—totes can hold multiple single-line orders or a multi-line order. Once a tote is full, it is palletized. Totes are returned to the first floor with the freight elevators and inducted (10) onto a multi-level conveyor line (11) and delivered to a packing station (12) on the first floor. Single line orders are automatically packed. Multi-line orders are sorted and packed for shipping. They are then conveyed and sorted (13) to the right shipping location (14). There is also a value-added services area (15) on the first floor level as well as a bombay sorter (16) for flats.